Efficient and cost-effective home casting furnace for metal projects

By:Admin

For centuries, metal casting has been a labor-intensive process that has required specialized equipment and expertise. However, a recent breakthrough in technology has revolutionized the way metal casting is done at home. The innovative Home Casting Furnace has made it possible for individuals to melt and cast metals in the comfort of their own homes, without the need for expensive equipment or extensive experience.

The Home Casting Furnace is a compact and efficient device that is designed for use by hobbyists, artists, and DIY enthusiasts who are interested in creating their own metal castings. It is a game-changer for those who have always wanted to try their hand at metal casting but have been deterred by the cost and complexity of traditional methods.

This revolutionary device is the brainchild of a team of engineers and designers at {Company Name}, a leading manufacturer of industrial equipment and tools. The company, founded in 1998, has a long history of innovation and has been at the forefront of developing cutting-edge solutions for various industries.

One of the key features of the Home Casting Furnace is its compact size, which makes it suitable for use in small workshops or even in a backyard setting. It is also incredibly easy to use, with a user-friendly interface that allows individuals to control the temperature and monitor the melting process with ease.

The furnace is capable of melting a wide variety of metals, including aluminum, bronze, and copper, allowing users to create a diverse range of castings for artistic or practical purposes. This versatility has made the Home Casting Furnace a popular choice among metalworkers, artists, and DIY enthusiasts.

In addition to its practicality and ease of use, the Home Casting Furnace is also an environmentally friendly option for metal casting. It is designed to be energy-efficient, with a low carbon footprint, and its compact size means that it requires minimal space for operation.

Furthermore, the furnace is equipped with safety features to ensure that users can operate it with peace of mind. This includes a thermal cutoff switch to prevent overheating and a durable, insulated design that minimizes the risk of accidents.

The launch of the Home Casting Furnace has been welcomed by the DIY community, with many individuals expressing excitement about the prospect of trying their hand at metal casting for the first time. This innovative device has opened up new possibilities for artistic expression and craftsmanship, allowing individuals to create unique and personalized metal castings without needing access to industrial facilities.

The Home Casting Furnace has also received praise from industry professionals, who recognize its potential to inspire a new generation of metalworkers and artisans. Its affordability and accessibility have made it a valuable tool for educational institutions and training programs, allowing students to gain hands-on experience in metal casting without the need for extensive resources.

Looking ahead, {Company Name} is committed to continuing its tradition of innovation and to further developing the Home Casting Furnace to meet the evolving needs of its users. With ongoing research and development, the company aims to enhance the capabilities of the furnace and to expand its range of applications, positioning it as a leading solution for metal casting in the home and small-scale production settings.

Ultimately, the Home Casting Furnace represents a significant advancement in the field of metalworking, democratizing access to metal casting and empowering individuals to unleash their creativity and craftsmanship. Its impact is already being felt across the DIY community, and it is poised to become a staple tool for anyone interested in exploring the art of metal casting.

Company News & Blog

Researchers Develop New Method for Creating Stronger Alloys

Arc Melting Technology Paves the Way for Innovative Applications in Material ScienceWhen it comes to material science, researchers have been constantly exploring ways of producing metals and alloys that exhibit superior quality and properties. The process of melting and casting metals has been a conventional technique for large-scale production of metals since the middle ages. However, the conventional process of furnace melting has limitations, such as poor homogeneity, impurity contamination, and poor quality of the final product. Therefore, technological advancements are being made to improve the efficiency and effectiveness of the melting and casting processes.One such advancement in the field of material science is the arc melting technology, which has revolutionized the way of producing high-quality metals and alloys. Arc melting involves melting materials using an electric arc, which transfers heat to the material through a graphite electrode. The heat from the arc melts the material, fusing it together to form a homogeneous mixture. This technology is efficient and fast, creating high-quality alloys that meet the stringent requirements of advanced industries.The arc melting technology is widely used in research laboratories and is gaining acceptance in industry applications ranging from aerospace to biomedicine. This is due to its ability to produce alloys with high purity, uniformity, and superior properties that are difficult or impossible to obtain with conventional melting techniques.One of the leading companies that specialize in arc melting technology is (need remove brand name), which is at the forefront of developing and producing advanced alloys. The company has a team of experts who work closely with customers to design and produce customized materials based on their specific needs and applications. (Need remove brand name) is known for providing high-quality materials with exceptional characteristics, such as high strength, thermal conductivity, and corrosion resistance, making them ideal for use in critical and challenging environments.The company has a fully equipped laboratory and manufacturing facility that allows them to carry out extensive research and development of new alloys. They use state-of-the-art equipment to ensure that every alloy produced meets the highest standards of quality and purity. Their products are widely used in aerospace, biomedicine, electronics, and many other critical applications.In the aerospace industry, arc melting has been instrumental in producing high-performance alloys that meet the stringent requirements of aircraft engines. The excellent thermal resistance and chemical stability of these alloys make them ideal for use in the harsh and demanding environment of jet engines.In the biomedical field, arc melting has enabled the production of advanced alloys that are biocompatible, making them suitable for implants and medical instrument applications. The high purity and uniformity of the alloys ensure that they do not cause any adverse reactions in the human body.In the electronics industry, arc melting has played a crucial role in the development of alloys that possess superior electrical and thermal conductivity properties. These alloys find widespread use in the production of microelectronic devices, such as transistors and sensors.The versatility and efficiency of arc melting technology have made it a game-changer in material science. Researchers and companies are continuously exploring new ways of using arc melting to create innovative alloys that have never existed before. The technology has opened up endless possibilities in the field of material science, making it possible to produce materials with unprecedented properties and functionality.In conclusion, arc melting technology is a powerful tool that has transformed the way of producing advanced alloys. The technology offers numerous advantages over conventional melting techniques, including high purity, uniformity, and quality of the final product. The technology is widely used in various industries because of its ability to create materials with exceptional characteristics that meet the stringent requirements of advanced applications. With companies such as (need remove brand name) at the forefront of developing and producing advanced alloys, the arc melting technology is poised to revolutionize the way we think, design, and manufacture materials.

High-Powered Tungsten Melting Furnace for Industrial Applications

The company is a leading manufacturer and supplier of industrial furnaces and heat treatment equipment. Their products are widely used in various industries including aerospace, automotive, energy, and mining. With a strong focus on quality and innovation, the company has earned a reputation for delivering reliable and efficient melting and heating solutions to its global customer base.The latest addition to their lineup is the Tungsten Melting Furnace, a highly advanced and versatile piece of equipment designed to meet the high demands of modern industrial applications. Built with precision and efficiency in mind, the Tungsten Melting Furnace is capable of melting and transforming tungsten, one of the hardest and highest melting point metals, into various forms and shapes with ease and precision.The Tungsten Melting Furnace is equipped with state-of-the-art heating elements and temperature control systems that ensure precise and uniform heating throughout the melting process. This not only improves the overall quality of the end product but also reduces energy consumption, making it an environmentally friendly choice for industrial operations. In addition, the furnace is designed for easy operation and maintenance, with user-friendly controls and remote monitoring capabilities.One of the key features of the Tungsten Melting Furnace is its ability to handle large quantities of tungsten at once, making it ideal for high-volume production processes. Whether it's for manufacturing tungsten alloys, sintering tungsten powders, or fabricating tungsten components, this furnace is up to the task. Its robust construction and reliable performance make it a valuable asset for any industrial operation that requires precision melting and shaping of tungsten materials.The company behind the Tungsten Melting Furnace takes pride in their commitment to excellence and customer satisfaction. They offer comprehensive support and service to ensure that their customers get the most out of their investment. From initial consultation and custom design to installation, training, and ongoing maintenance, the company's team of experts is dedicated to delivering top-notch solutions that meet the unique needs of each customer.Furthermore, the company is known for its continuous research and development efforts to stay ahead of the curve in the ever-evolving industrial furnace industry. They work closely with their customers and partners to gather feedback and insights that help drive innovation and improve their product offerings. With an extensive network of sales and service locations around the world, they are well-positioned to provide timely support and assistance to customers in any location.In summary, the Tungsten Melting Furnace from this company is a testament to their dedication to innovation and quality. It is a highly advanced and efficient piece of equipment that offers precise and reliable melting and shaping of tungsten materials, making it a valuable asset for any industrial operation. With a strong focus on customer satisfaction and a commitment to continuous improvement, the company behind this furnace is poised to remain a leader in the industrial furnace industry for years to come.

Efficient Aluminum Crucible Furnaces: A Game-Changer in the Industry

Aluminum Crucible Furnace: A Revolutionary Solution for Melting MetalsIn today's fast-paced world, the demand for precision and speed is higher than ever before. Every industry aims to be more efficient and productive to stay ahead of the competition and meet the demands of their customers. One such industry is the metallurgical industry that requires melting metals to create alloys and other derivatives. Understanding the need for efficiency and speed, {Company Name} has introduced an innovative solution, the Aluminum Crucible Furnace, which provides a revolutionary way of melting metals.The Aluminum Crucible Furnace is a unique concept that is designed for melting and casting all types of alloys and metals with the utmost precision and accuracy. The furnace is extremely energy-efficient and reduces energy consumption by up to 50% compared to the traditional furnaces. It is also an eco-friendly option that reduces greenhouse gas emissions and thus helps to preserve the environment.The Aluminum Crucible Furnace is built using the latest technological advancements and is a fully automated system that is easy to operate. The furnace is equipped with state-of-the-art sensors that help to regulate the temperature and maintain a consistent melt quality. The furnace has an ergonomic design that reduces operator fatigue, and it is built to withstand the harsh working conditions of a metallurgical environment.The furnace has a capacity of up to 2000 kg and can operate for extended periods without the need for frequent maintenance. The Aluminum Crucible Furnace is a safe and reliable option for melting and casting alloys and metals, and it can help to boost productivity, reduce costs, and improve the quality of the final product.{Company Name} is a leading manufacturer of metallurgical equipment and has been providing innovative solutions to the industry for over a decade. The company is committed to providing the best quality products and services to its customers and has a reputation for excellence in the market. {Company Name} has a team of experts who are dedicated to researching and developing new solutions that cater to the changing needs of the industry.The introduction of the Aluminum Crucible Furnace is a testament to the company's commitment to innovation and excellence. The furnace is already gaining popularity in the industry, and many customers have reported significant improvements in their productivity and efficiency after switching to this new technology.In summary, the Aluminum Crucible Furnace is a revolutionary solution that offers significant benefits over traditional furnaces. It is energy-efficient, eco-friendly, and easy to operate, making it an ideal choice for melting and casting alloys and metals. {Company Name}'s commitment to innovation and quality has made it a leader in the metallurgical equipment industry, and the Aluminum Crucible Furnace is another feather in its cap.

High-Efficiency Industrial Steel Melting Furnace for Reliable Metal Production

Steel Melting Furnace Revolutionizes Manufacturing IndustryThe manufacturing industry has experienced a significant shift with the introduction of the cutting-edge Steel Melting Furnace. Developed by {}, this groundbreaking technology has redefined the steel manufacturing process, delivering unparalleled efficiency and precision.The Steel Melting Furnace is a state-of-the-art piece of equipment that is designed to melt and refine steel with remarkable speed and accuracy. With a high-powered heating system and advanced control mechanisms, this furnace has the capability to convert raw materials into high-quality molten steel in a fraction of the time it takes traditional melting methods.One of the key features of the Steel Melting Furnace is its advanced temperature control system, which ensures that the steel is melted at the precise temperature required for the specific application. This level of precision not only improves the quality of the steel produced but also reduces energy consumption, making it a more sustainable option for steel manufacturing.Furthermore, the furnace is equipped with a robust filtration system that effectively removes impurities from the molten steel, resulting in a purer end product. This is crucial for industries that require high-quality steel with minimal impurities, such as automotive and aerospace manufacturing.In addition to its technical capabilities, the Steel Melting Furnace also offers a user-friendly interface that allows operators to monitor and control the melting process with ease. This intuitive system streamlines the manufacturing workflow, reducing the potential for human error and maximizing productivity.According to {}, the company behind the Steel Melting Furnace, this technology represents a significant advancement in the steel manufacturing industry. "We are proud to introduce the Steel Melting Furnace, which is poised to revolutionize the way steel is produced," said a spokesperson for the company. "This technology is the result of years of research and development, and we are confident that it will set a new standard for efficiency and quality in steel manufacturing."The impact of the Steel Melting Furnace is already being felt across the manufacturing landscape. Companies that have adopted this technology have reported significant improvements in their production processes, including faster melting times, higher quality steel, and reduced operating costs. This has led to increased competitiveness and profitability for these businesses, positioning them as leaders in the industry.Moreover, the environmental benefits of the Steel Melting Furnace cannot be overlooked. By reducing energy consumption and minimizing waste, this technology aligns with the growing demand for sustainable manufacturing practices. As a result, companies that utilize the Steel Melting Furnace are not only improving their bottom line but also demonstrating their commitment to environmental responsibility.Looking ahead, the potential for the Steel Melting Furnace to further transform the manufacturing industry is immense. With ongoing advancements and refinements, this technology is expected to continue pushing the boundaries of what is possible in steel manufacturing. As more companies recognize the advantages of the Steel Melting Furnace, its influence is likely to expand, spurring innovation and raising the bar for the entire industry.In conclusion, the Steel Melting Furnace developed by {} is a game-changer for the manufacturing industry. Its combination of advanced technology, user-friendly design, and environmental benefits makes it a highly valuable asset for companies seeking to enhance their steel manufacturing capabilities. As this technology continues to gain traction, it has the potential to drive significant progress and shape the future of steel production.

Highly efficient arc melting furnace for metal production and research applications

A leading manufacturing company has recently announced the successful installation of a state-of-the-art Arc Melting Furnace at their production facility. The new furnace is set to revolutionize the company's manufacturing process, allowing for greater precision and efficiency in the creation of high-quality steel and alloy products.The Arc Melting Furnace, which was custom-built to meet the company's specific requirements, is equipped with advanced technology that enables it to reach extremely high temperatures, melting and refining various types of metal and alloy materials. This cutting-edge equipment boasts a robust design that is capable of withstanding the intense heat generated during the melting process, ensuring long-term reliability and performance.In addition to its impressive capabilities, the Arc Melting Furnace is also equipped with advanced control systems that enable precise temperature regulation and alloy composition control. This level of control is crucial for the company's manufacturing operations, as it allows for the creation of highly specialized steel and alloy products that meet the stringent quality standards demanded by their clients.The installation of the Arc Melting Furnace is part of the company's ongoing commitment to investing in advanced manufacturing technologies. By incorporating the latest equipment into their production processes, the company aims to stay ahead of the competition and continue to deliver innovative and high-quality products to their customers."We are thrilled to announce the successful installation of our new Arc Melting Furnace," said a spokesperson for the company. "This cutting-edge equipment represents a significant milestone for us and reaffirms our dedication to delivering exceptional quality and value to our customers. With the capabilities of this furnace, we are confident that we will be able to expand our product offerings and meet the evolving needs of the market."The company, which has been in operation for over [number] years, has built a strong reputation for excellence in the manufacturing of steel and alloy products. Their commitment to quality and innovation has earned them a loyal customer base and positioned them as a leader in the industry.In addition to the installation of the Arc Melting Furnace, the company has also recently expanded its production facility, adding new manufacturing lines and increasing its overall capacity. These strategic investments are aimed at supporting the company's growth trajectory and positioning them for continued success in the years to come.As the company looks to the future, they remain dedicated to pushing the boundaries of what is possible in steel and alloy manufacturing. With the addition of the Arc Melting Furnace and the expansion of their production capabilities, they are well-positioned to continue delivering cutting-edge products to their customers and drive innovation in the industry.The installation of the Arc Melting Furnace is a testament to the company's commitment to excellence and their willingness to invest in the latest technologies to stay at the forefront of the industry. As they continue to push the boundaries of what is possible, the company is poised for continued success and growth in the years to come.

Top Uses of Insulation Bricks in Construction Projects

Insulation bricks are a vital component in many construction and industrial projects, providing thermal and acoustic insulation for buildings and equipment. These bricks are manufactured using high-quality materials and advanced techniques, ensuring their effectiveness in maintaining temperature and reducing noise levels. [Company Name] is a leading manufacturer of insulation bricks, known for their exceptional quality and innovative products. With a strong commitment to customer satisfaction and continuous improvement, [Company Name] has established itself as a trusted partner for various construction and industrial applications.[Company Name] uses state-of-the-art technology and modern production facilities to create insulation bricks that meet the highest standards of performance and durability. Their team of experienced engineers and technicians are dedicated to developing new and improved products that cater to the evolving needs of their customers. By staying at the forefront of industry trends and advancements, [Company Name] is able to offer a wide range of insulation bricks that are suitable for diverse applications.One of the key uses of insulation bricks is in the construction of commercial and residential buildings. These bricks are installed in walls, roofs, and floors to provide thermal insulation, helping to regulate indoor temperature and reduce energy consumption. Additionally, insulation bricks also contribute to acoustic insulation, minimizing the transmission of sound between different parts of a building. This is essential in creating a comfortable and peaceful environment for occupants, particularly in urban areas with high levels of noise pollution.In industrial settings, insulation bricks play a crucial role in maintaining the operational efficiency of various equipment and machinery. They are used in kilns, furnaces, and ovens to contain heat and prevent energy loss, enhancing the overall performance and longevity of these assets. Moreover, insulation bricks are employed in the construction of chimneys and flues, creating a safe and well-insulated environment for the expulsion of by-products from industrial processes.[Company Name] understands the importance of delivering reliable and cost-effective insulation solutions, and their range of insulation bricks is designed to meet the specific requirements of each project. They offer a variety of shapes, sizes, and thermal properties, ensuring that customers have access to the perfect product for their needs. With a focus on sustainability, [Company Name] also prioritizes the use of eco-friendly materials and production processes, aligning with the growing demand for environmentally responsible building solutions.As a company, [Company Name] prides itself on its commitment to excellence and continuous improvement. They have implemented strict quality control measures throughout the manufacturing process to guarantee the reliability and durability of their insulation bricks. Additionally, their team places a strong emphasis on customer service, working closely with clients to understand their unique needs and provide tailored solutions that exceed expectations.In line with their dedication to innovation, [Company Name] continues to invest in research and development to create advanced insulation bricks that address emerging industry challenges. By remaining proactive and adaptable, they have positioned themselves as a leader in the insulation industry, trusted by a diverse range of customers for their expertise and reliability.With a reputation for delivering high-quality products and unparalleled service, [Company Name] has become a go-to source for insulation bricks in various markets. Their commitment to excellence, innovation, and sustainability sets them apart as a preferred partner for construction and industrial projects, ensuring that customers receive the best insulation solutions for their needs. Moving forward, they will continue to lead the way in the development of cutting-edge insulation technologies, driving the industry towards a more sustainable and efficient future.

Ceramic Fiber Products: Unveiling the Latest Innovations in Heat Insulation

Title: Enhanced Insulation Solution: Isowool Introduces Groundbreaking Ceramic Fiber TechnologyIntroduction (150 words):Isowool, a leading innovator in insulation solutions, has announced a groundbreaking technology in the field of ceramic fibers. Built upon decades of research and development, the new product aims to revolutionize insulation systems across industries with enhanced thermal performance, durability, and energy efficiency. This cutting-edge ceramic fiber, devoid of hazarous materials, offers a sustainable solution while fulfilling the stringent safety standards that are mandated across various sectors. Isowool's commitment to delivering superior insulation products, combined with their extensive expertise in thermal insulation, make them well-positioned to address the increasing market demands for sustainable, durable, and high-performance thermal management solutions.Body:1. Advancements in Ceramic Fiber Technology: Meeting Industry Demands (200 words)Isowool's latest ceramic fiber technology represents a significant leap in the field of insulation solutions. This revolutionary offering combines superior thermal insulation properties with sustainable and environmentally friendly aspects, placing it at the forefront of the industry. Isowool's product emerges as a reliable solution that promises to drive energy efficiency, reduce carbon footprint, and improve productivity across various sectors, from manufacturing to construction.The use of advanced materials and cutting-edge manufacturing processes ensures the durability and longevity of the ceramic fiber. Isowool's ceramic fiber is capable of withstanding high temperatures and resisting chemical or mechanical stresses, making it an ideal choice for challenging and demanding applications. The product's superior thermal properties contribute to energy conservation and cost-effectiveness, thereby making it an attractive solution for businesses across diverse industries. 2. Applications Across Industries: Versatility and Adaptability (200 words)One of the key advantages of Isowool's ceramic fiber is its versatility and adaptability to various industrial applications. Its high-temperature resistance and ability to withstand harsh environments make it an ideal choice for industries such as metal processing, power generation, automotive, aerospace, and more. In metal processing, where high-temperature furnaces and kilns are utilized, Isowool's ceramic fiber provides excellent insulation, ensuring energy efficiency and cost savings. The automotive and aerospace sectors benefit from the product's lightweight nature and exceptional thermal insulation, enhancing both fuel efficiency and passenger comfort.Furthermore, Isowool's ceramic fiber finds extensive use in the construction industry, addressing insulation needs across commercial, residential, and infrastructure development projects. By providing a high level of fire resistance and thermal insulation, the product helps in promoting sustainable and energy-efficient construction practices.3. Sustainability and Safety: Complying with Environmental Norms (200 words)In line with global sustainability goals, Isowool's ceramic fiber technology stands as a testament to their commitment to environmental consciousness. Unlike traditional insulation materials, Isowool's solution is free from hazardous substances such as asbestos, reducing health risks for both installers and end-users.Additionally, Isowool's streamlined manufacturing processes prioritize energy efficiency and low waste generation, thereby minimizing the company's carbon footprint. Incorporating this environmentally friendly insulation product can contribute significantly to meeting energy consumption reduction targets and building eco-friendly infrastructures.Moreover, the elimination of hazardous materials complies with strict industry safety standards, ensuring a safer working environment for employees and reducing the risk of occupational health issues. Isowool's focus on sustainable and safe products sets a benchmark for the industry, urging other insulation manufacturers to follow suit and prioritize environmentally responsible solutions.Conclusion (150 words):Isowool's introduction of their innovative ceramic fiber technology propels the insulation industry toward sustainable and energy-efficient practices. With its enhanced thermal properties, adaptability across diverse industries, and commitment to sustainability and safety, Isowool's ceramic fiber is set to redefine the status quo of thermal insulation systems. This groundbreaking product caters to the demands of numerous sectors, from manufacturing to construction, providing them with a reliable, durable, and high-performance solution that contributes to a greener tomorrow. As their cutting-edge insulation solution continues to gain traction, Isowool stands as a vanguard of technological progress, propelling various industries toward a more sustainable and energy-efficient future.

Exploring the Benefits of Ceramic Cloth Insulation for Enhanced Energy Efficiency

Ceramic Cloth Insulation Revolutionizing Heat Control in IndustriesInnovation and sustainable solutions have become increasingly important in today's industrial landscape. Industries are constantly seeking ways to enhance efficiency, reduce energy consumption, and mitigate environmental impacts. One company emerging as a frontrunner in this quest is {Ceramic Cloth Insulation}, whose cutting-edge product is revolutionizing heat control in various sectors.{Ceramic Cloth Insulation}, a global leader in thermal management solutions, has developed a highly advanced material that provides superior insulation capabilities. Designed to withstand extreme temperatures and harsh conditions, their product has garnered immense attention from industries ranging from aerospace to automotive manufacturing, and even energy production.The key to {Ceramic Cloth Insulation}'s success lies in its unique composition. Made from a blend of high-quality ceramic fibers and specialized fabrics, the insulation material possesses exceptional thermal resistance characteristics. This innovative technology enables industries to effectively control and manage heat, achieving significant operational efficiencies.With the ability to withstand temperatures of up to 1,800 degrees Celsius, {Ceramic Cloth Insulation} ensures the utmost safety for industries operating under extreme conditions. This breakthrough development not only enhances the longevity of equipment but also reduces maintenance costs, making it an attractive choice for companies across the board.One of the primary advantages of {Ceramic Cloth Insulation} is its versatility. The material's flexibility allows for easy handling and installation, making it ideal for a wide range of applications. Whether it's insulating pipes in chemical plants, lining furnaces in steel manufacturing, or protecting cables in the aerospace industry, this product proves to be a versatile solution for heat management needs.Moreover, this innovative insulation material acts as a barrier to prevent unnecessary heat transfer. By significantly reducing heat loss and maximizing thermal efficiency, {Ceramic Cloth Insulation} contributes to substantial energy savings for industrial plants. This not only lowers operational costs but also aligns with industries' growing focus on sustainable practices.The positive impact of {Ceramic Cloth Insulation} on the environment cannot be overlooked. By reducing energy consumption, industries using this insulation material are effectively lowering their carbon footprint. This aligns with global efforts to combat climate change and promote sustainability, making {Ceramic Cloth Insulation} an essential component of the transition towards greener industrial practices.To further cater to industries' diverse needs, {Ceramic Cloth Insulation} offers a range of customized solutions. Their team of experts collaborates closely with clients to understand specific requirements and provide tailored insulation solutions that maximize efficiency. This customer-centric approach has earned {Ceramic Cloth Insulation} a reputation for excellence and reliability.As demand for innovative thermal management solutions continues to grow, {Ceramic Cloth Insulation} remains committed to pushing the boundaries of technology. Through ongoing research and development, the company aims to further enhance the performance of their insulation material and expand its application in various industries.By leveraging their expertise in thermal management, {Ceramic Cloth Insulation} is not only transforming heat control practices but also contributing to industrial efficiency and sustainability. With their advanced insulation solutions, industries can maximize operational productivity while reducing energy consumption and minimizing environmental impacts.In conclusion, the innovative and adaptable nature of {Ceramic Cloth Insulation} has positioned the company as a leader in thermal management solutions. With their exceptional insulation material, industries can now effectively control heat, ensuring safety, efficiency, and sustainability across various sectors. As the demand for sustainable practices continues to increase, {Ceramic Cloth Insulation} remains at the forefront of technological advancements in the industry.

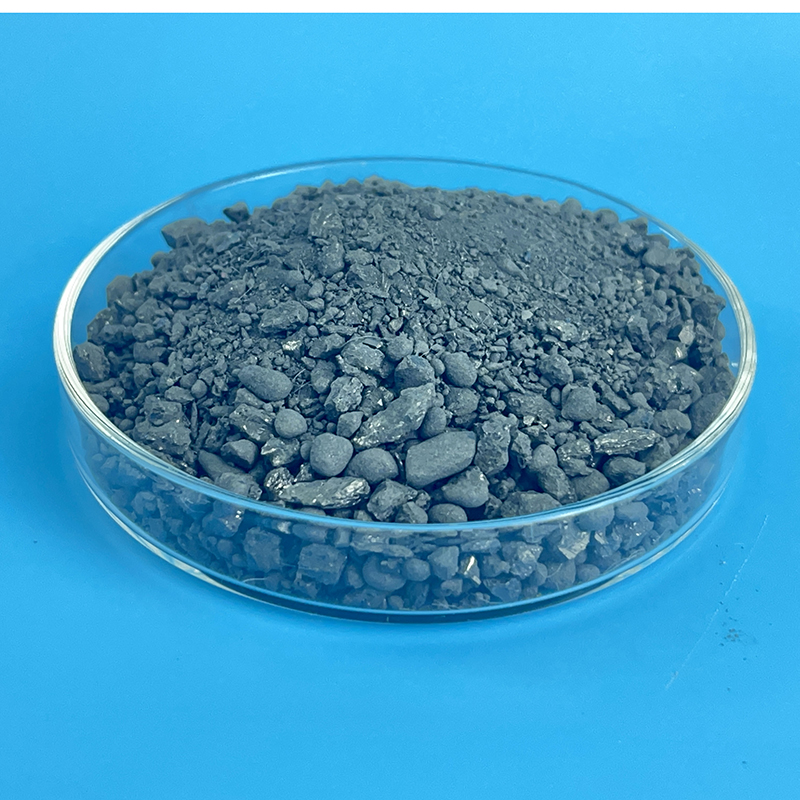

High quality carbon bricks for high temperature applications

Magnesia Carbon Brick widely used in steel industry for lining applications, such as converters, AC and DC EAF, ladle and ladle furnace, and has achieved good results in industrial applications.Magnesia Carbon Brick is a type of refractory material used in the lining of high temperature furnaces and vessels in industries such as steel, cement, and non-ferrous metals. The bricks are made from a mixture of high purity magnesite and graphite, which gives them excellent resistance to thermal shock, high temperature erosion, and corrosion from molten steel and slag.{}Magnesia Carbon Brick Co., Ltd. is a leading manufacturer and supplier of Magnesia Carbon Brick products. With a strong focus on research and development, the company has been able to develop innovative products that meet the demanding requirements of modern industrial applications. The company prides itself on its commitment to quality, reliability, and customer satisfaction.Magnesia Carbon Brick Co., Ltd. has a state-of-the-art production facility that is equipped with the latest technology and machinery for manufacturing Magnesia Carbon Brick products. The company's production process adheres to strict quality control measures to ensure that the products meet the highest standards of performance and durability.The company also has a team of highly skilled and experienced engineers and technicians who are dedicated to providing technical support and customized solutions to meet the specific needs of its customers. With a strong emphasis on innovation and continuous improvement, Magnesia Carbon Brick Co., Ltd. strives to stay ahead of the curve in the refractory industry.In addition to its commitment to quality and innovation, Magnesia Carbon Brick Co., Ltd. is also dedicated to environmental sustainability. The company employs environmentally friendly production processes and uses raw materials that are sourced from responsible suppliers. This ensures that the company's products have minimal impact on the environment.As a result of its dedication to excellence and customer satisfaction, Magnesia Carbon Brick Co., Ltd. has built a strong reputation in the industry and has established long-term partnerships with many leading companies in the steel and refractory sectors.The company's Magnesia Carbon Brick products have been widely used in various steel industry applications, including converters, AC and DC EAF, ladles, and ladle furnaces. The superior performance and durability of these products have made them the preferred choice for many steel manufacturers, who rely on Magnesia Carbon Brick Co., Ltd. for their refractory needs.The company's commitment to quality, innovation, and sustainability has positioned it as a trusted leader in the refractory industry. With a focus on customer satisfaction and continuous improvement, Magnesia Carbon Brick Co., Ltd. is well-positioned for long-term success and growth in the global market.In conclusion, Magnesia Carbon Brick Co., Ltd. is a leading manufacturer and supplier of high-quality Magnesia Carbon Brick products. With a strong emphasis on quality, innovation, and sustainability, the company has established itself as a trusted partner for many steel manufacturers and has earned a strong reputation in the industry. As the demand for refractory materials continues to grow, Magnesia Carbon Brick Co., Ltd. is well-equipped to meet the needs of the market and continue its success in the future.